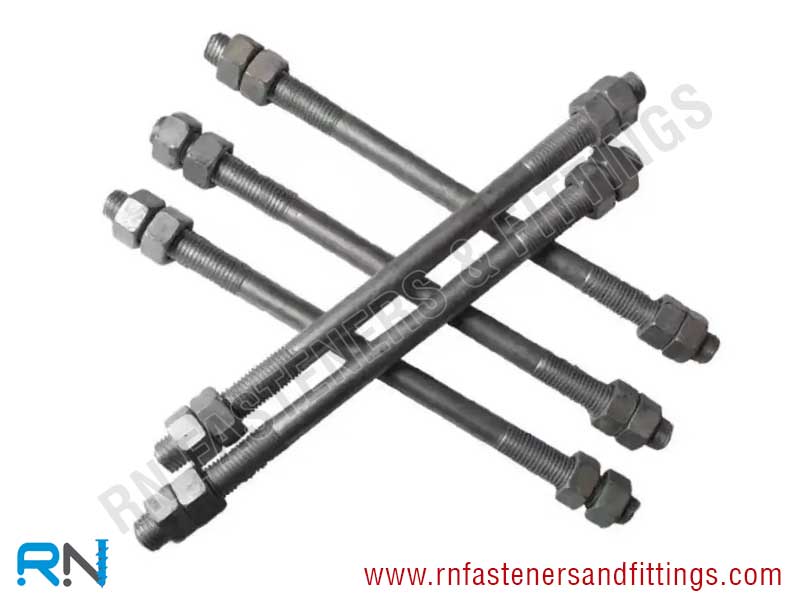

RN Fasteners and Fittings Pvt. Ltd. are manufacturers, suppliers and exporters of Threaded Studs in India, Ludhiana. Threaded studs are fasteners with threads on both ends, designed to be inserted into a pre-drilled hole or attached to a surface using nuts or other threaded components. These studs are commonly used in various applications across industries such as construction, manufacturing, automotive, and electronics. They serve as a means to create secure connections, fasten objects, and provide structural support. Here are some key characteristics and uses of threaded studs:

Thread Types: Threaded studs can have threads of various types, including standard threads (Unified Thread Standard or UTS), metric threads, or specialized threads tailored to specific applications.

Materials: Threaded studs are typically made from materials such as steel (carbon or stainless), brass, aluminum, or exotic alloys, depending on the required strength, corrosion resistance, and environmental conditions.

Thread Length: Threaded studs come in different lengths, typically with threads extending from both ends. The length of the threads on each end can vary, allowing for versatility in connecting components of varying thicknesses.

Head Types: Threaded studs may have different head configurations on one end, such as hex heads, flat heads, or round heads, depending on the intended use and preference for tools.

Applications:

Fastening: Threaded studs are used to fasten two or more objects together securely. They can be screwed into a pre-drilled hole or attached to a surface using nuts, bolts, or other threaded components.

Welding: In some applications, threaded studs are welded to surfaces to provide secure anchor points for various fixtures and equipment.

Electronics: Threaded studs are often used in electronic and electrical equipment to mount components, such as circuit boards or transformers, onto chassis or enclosures.

Construction: In construction, threaded studs can be used to anchor structural elements, secure equipment, or attach building components.

Weldable vs. Non-Weldable: Some threaded studs are specifically designed for welding applications, featuring a weldable base that can be permanently fused to a surface through welding processes like arc welding or stud welding.

Corrosion Resistance: Depending on the environmental conditions and materials involved, it may be necessary to choose threaded studs made from corrosion-resistant materials, such as stainless steel or brass, to ensure long-term durability.

Threaded Stud Accessories: To complete connections using threaded studs, various accessories like nuts, washers, flanges, and anchors may be required. These components help secure the threaded stud in place and ensure a stable connection.

Threaded studs provide a reliable and flexible means to join components, secure objects, and create structurally sound connections in a wide range of applications. Their versatility and availability in various materials, sizes, and thread types make them valuable fasteners in many industries.