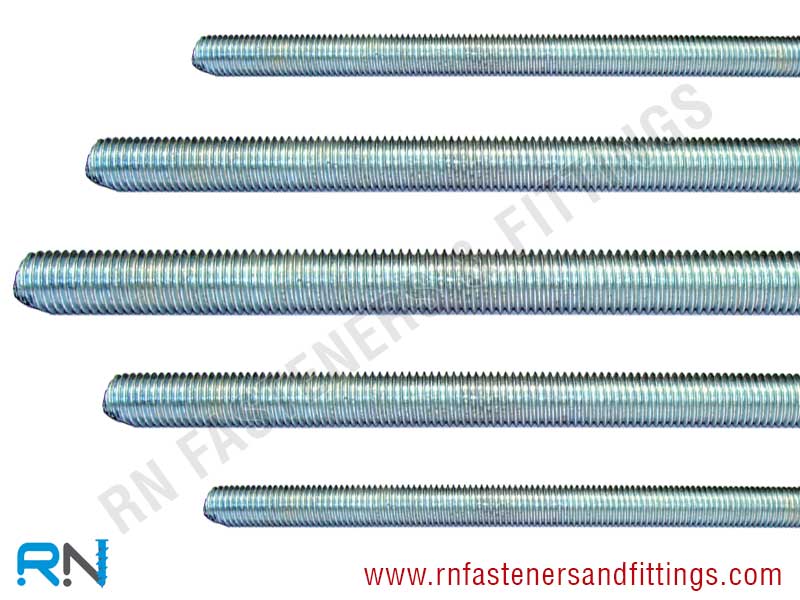

RN Fasteners and Fittings Pvt. Ltd. are manufacturers, suppliers and exporters of DIN 975 / DIN 976 threaded rods in India, Ludhiana. A threaded rod, also known as a threaded bar or stud, is a long, straight piece of metal with external threads running along its entire length. These external threads allow for nuts, washers, and other fasteners to be screwed onto the rod, making it a versatile component used in various applications for joining and fastening objects together.

Key features of threaded rods include:

Threads: The most distinguishing characteristic of a threaded rod is its threaded surface, which allows for a secure connection when combined with compatible nuts or other threaded components.

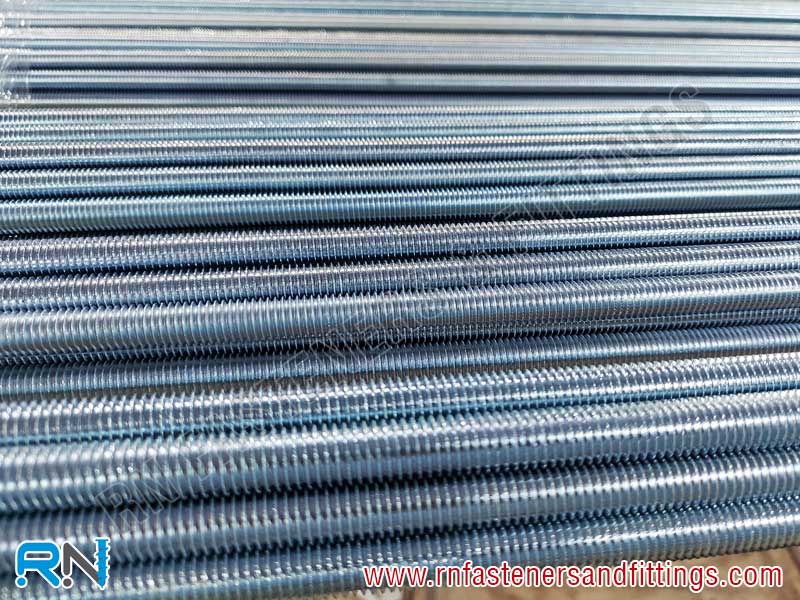

Material: Threaded rods can be made from various materials, including steel, stainless steel, aluminum, brass, and more. The choice of material depends on the specific application's requirements, such as strength, corrosion resistance, or weight.

Length: Threaded rods come in various lengths, typically ranging from a few inches to several feet. Longer rods can be cut to the desired length if needed.

Thread Type: Threaded rods can have different types of threads, including standard (often referred to as Unified Thread Standard or UTS), metric, or specialized thread forms for specific applications.

Common uses of threaded rods include:

Construction: Threaded rods are frequently used in construction projects for bracing, anchoring, and supporting structures. They can be embedded in concrete or used as tie rods to connect structural elements.

Fastening: Threaded rods are used in conjunction with nuts, washers, and other fasteners to secure objects together, such as in machinery, furniture assembly, or automotive applications.

Electrical and Plumbing: In electrical and plumbing installations, threaded rods may be used to mount equipment, fixtures, or conduit to walls, ceilings, or floors.

DIY Projects: Threaded rods are often used in do-it-yourself (DIY) projects for creating custom brackets, hangers, and supports.

Suspension Systems: In automotive and mechanical engineering, threaded rods can be part of suspension systems, adjusting the height or alignment of components.

Manufacturing: Threaded rods are used in manufacturing processes for jigs, fixtures, and other tooling applications.

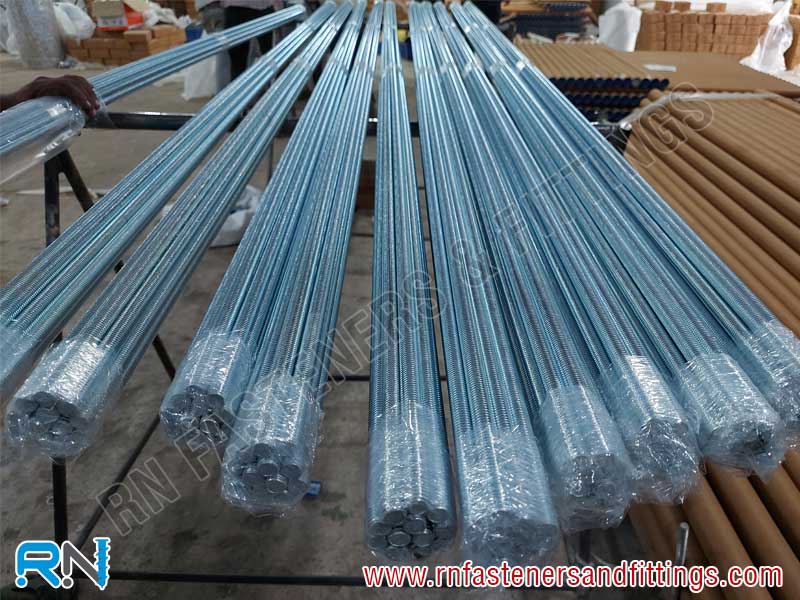

Specifications:

Low Carbon: Plain, Zinc, Hot dipped galvanized and Yellow

ASTM A307 & A193B7: Plain, Zinc and Yellow

Stainless Steel: 18-8: 304 and 316

Metric Rod: DIN975 & 976 in Class 4.8 , 8.8 & 10.9

Threads: UNC , UNF , MM & BSW, right hand, left hand, and ACME

Diameters: M6 to M64 & ¼” to 2-1/2”

Length: 1Mtr. To 3Mtrs. & 1feet to 12feet

| Size | Wt Per 100 Feets in KGS | Pieces Per Tube |

| 1/4-20 | 5.50 | 50 |

| 5/16-18 | 9.00 | 35 |

| 3/8-16 | 13.25 | 25 |

| 7/16-14 | 17.60 | 17 |

| 1/2-13 | 23.00 | 12 |

| 9/16-12 | 29.85 | 10 |

| 5/8-11 | 38.00 | 2 |

| 3/4-10 | 55.25 | 5 |

| 7/8-9 | 74.75 | 4 |

| 1-8 | 100.00 | 3 |

| 1 1/-2-6 | 232.50 | 1 |

| 2"-4 1/2 | 400.55 | 1 |

| THREADED RODS DIN 975 (DIN 976-1) | ||

| L, mm | 1000 | 2000 |

| M3 | 0,10 | 0,20 |

| M4 | 0,12 | 0,24 |

| M5 | 0,15 | 0,30 |

| M6 | 0,17 | 0,34 |

| M8 | 0,30 | 0,60 |

| M10 | 0,48 | 0,96 |

| M12 | 0,70 | 1,40 |

| M14 | 0,95 | 1,90 |

| M16 | 1,30 | 2,60 |

| M18 | 1,60 | 3,20 |

| M20 | 2,00 | 4,00 |

| M22 | 2,50 | 5,00 |

| M24 | 3,00 | 6,00 |

| M27 | 3,73 | 7,46 |

| M30 | 4,69 | 9,37 |

| M33 | 5,78 | 11,56 |

| M36 | 6,80 | 13,60 |

| M39 | 11,29 | 22,57 |

| M42 | 9,53 | 19,06 |

| M48 | 12,20 | 24,40 |

| M52 | 16,75 | 33,50 |

| M56 | 20,05 | 40,11 |

| Weight kg/1pcs | ||